high speed nail collating machine

- roofing nail collator

- big cap coil nail making machine

- coiling welding making machine price

- coil nail making machine with plastic rubber binding

high speed wire roofing nail coil screw collator coiling welding making machine price machine for power plastic rubber binding Available

Raw Material for nail making machine: Normal wire, new metal wire, waste rebar, scrap steel bar, hard-drawn wire, waste electrode, and other kind of waste steel.

Process of nail making: Wire-Rod → Wires-Drawing → Nail-Making → Polishing →Rolling→Coiling→ Packing → Delivery coil nails

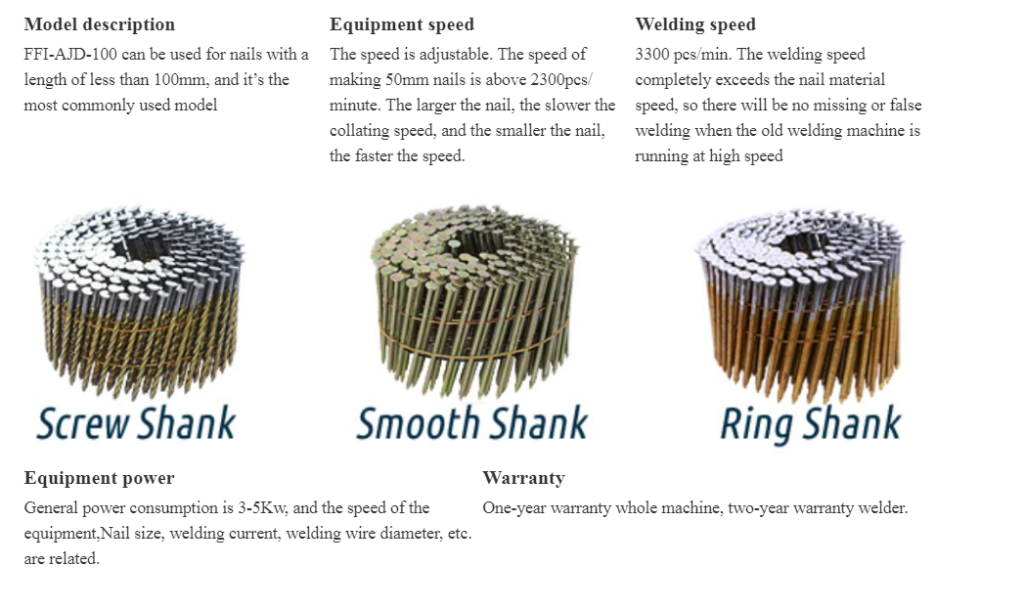

Application The coil nail collating machine is used for collating loose nail into coil.,then use coil nail with nail gun.

Coil nails Process of nail making: Wire-Rod → Wires-Drawing → Nail-Making → Polishing →Rolling→Coiling→ Packing → Delivery

There are mainly 2 types of coil nail making machine:

- Semi Automatic coil nail welding machine Machine Features: High frequency welding can ensure bigger weld point and firmly welding, no loose welding or lack of welding.

- Auto rubber banding coil nail making machine: Small welding spark, safer, Better quality vibration plate, smoothly feeding, no nail stuck, easy adjusting.

Machine body with thicker and high quality material.

Characteristic of the High speed automatic coil nail making machine

- The coiled nail is automatically formed and bound with rubber bands. The finished coil nails are produced automatically and pushed onto the platform. The finished coiled nails must still be caught by hand to improve their performance.

- An improved platform for finished products: The platform can hold approximately 60 coil nails and can be adjusted to adjust the product’s direction.

- New improved welding base: There is no need to adjust the height to accommodate different sizes of welding wheel (for example, do 19-37 welding position nail heights, the welding base can be adjusted). This reduces welding waste and meets technical requirements.

- New patent coil nail cutting technology: The probability of continuous cutting is less than one-tenth of the usual typical. This reduces the waste rate.

- Improved automatic operation: Additional protection for burned or used welding wire, protection for uncut coiled nails, and protection of rubber bands. Display its position on the touch screen.